Understanding the facility

On the University of Bath campus, we have a research-grade facility for making optical fibre. We use the facility to process raw materials – usually silica glass tubes and doped silica rods – into flexible optical fibre that guides light along its length. We make many different types of fibre, most of which is very different to conventional telecommunications fibre and often incorporates a microstructure.

The facility is housed in a cleanroom suite and consists of two drawing towers along with ancillary space for storing and processing glass. Each tower has a furnace that can heat glass up to over 2000 degrees Celsius. One tower is suitable for forming inflexible components such as capillaries and preforms, while the other has the winding gear required to collect fibre as it is drawn as well as apparatus for applying and curing a polymer coating to protect it.

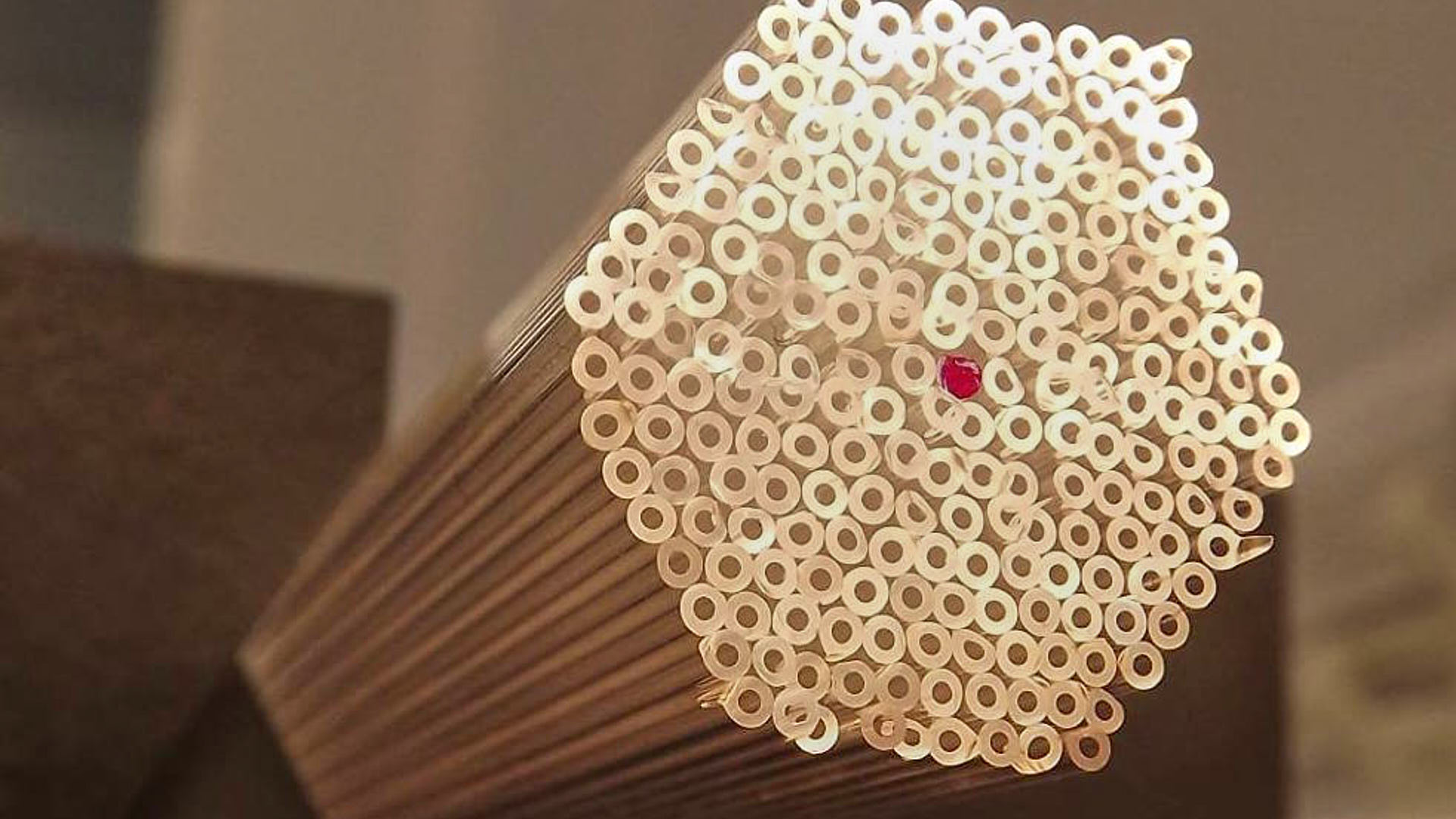

Typically, the fabrication procedure that we use is the 'stack-and draw' technique. First, tubes or rods are heated and stretched into capillaries that can be stacked by hand into a large-scale version of the structure that we want inside the fibre. The resulting preform is then itself heated and drawn into fibre in two stages. As the cross-section is reduced we take care to maintain the structure, for example by pressurising the holes in the preform to prevent them from collapsing.

Read more about how optical fibres are made.

Fibre fabrication and our research

Fibre fabrication forms a significant part of our research effort. Partly, this is about creating new fibre with capabilities beyond those available with existing designs. Examples include the novel hollow-core fibres developed recently as well as new endoscopic imaging fibres. On the other hand, many of our fibres are based on existing designs fabricated with a specific end-goal in mind, for example to develop single photon sources or quantum memories.

The ethos of our facility is driven by the active involvement of researchers. It is very important to us that PhD students, postdoctoral researchers, and long-term academic visitors learn to use the facility for themselves, gaining insight into the fabrication process that in turn feeds back into shaping our research directions.

Read more about the research made possible by our fibre fabrication facility:

Collaboration and user access

Within our research Centre, we have expertise that spans the entire process of design, modelling, fabrication, characterisation, and application of novel optical fibre. While we do not supply fibre commercially, we are always keen to explore new partnerships and discuss research problems that we may be able to solve by developing new fibre.

We run a professional development course in optical fibre fabrication, taught by experienced members of staff from the CPPM. Delegates gain hands-on experience of the complete cycle from theory and design, through fabrication, to characterisation in an intensive course that is tailored towards their individual interests. Contact us below for more information.

In addition, our facility is available for use by external clients. We can provide technical support and consultation to ensure that external users maximise the benefits of using the fibre fabrication facility. Email us at the address below to find out more.