We can measure fluid-born noise characteristics of positive displacement hydraulic pumps using the secondary source test method. This forms the basis of British Standard BS6335 pt. 1 and ISO 10767-1: 1996 for the rating of pump fluid-borne noise. We can also use this method to test hydraulic motors, valves and hoses.

We use the secondary source method to determine the flow ripple and impedance of hydraulic components. Flow ripple provides very useful information which would be difficult to achieve by other means. Yet, it is very difficult to measure directly. However, we can determine it indirectly in the secondary source method by mathematical analysis of pressure ripple measurements at three points along a pipe. The FBN package performs data acquisition, analysis and plotting for the test method.

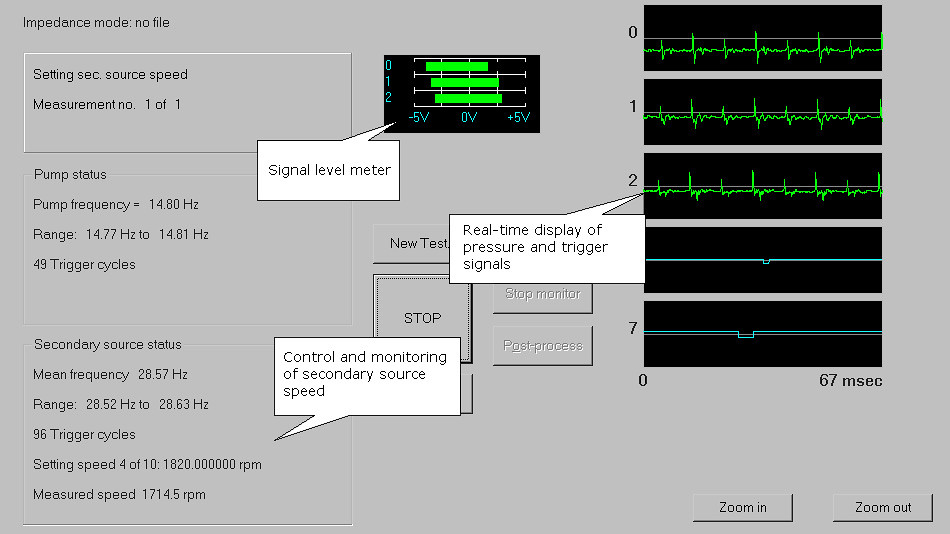

FBN user interface

FBN runs on a PC using a high speed data acquisition card. The software offers high productivity. We can process and display results graphically within seconds of initiating a measurement.

Our FBN software is used by several pump and system manufacturers in-house. It is used for testing a wide range of piston, gear, vane, gerotor and plunger pumps, as well as motors, accumulators, hoses and valves. It has proved particularly effective in testing automotive power steering pumps and flexible hoses. This has led to improved designs for pumps and systems.

FBN Features

- high-speed data acquisition with sophisticated order tracking and excellent frequency resolution

- calculation of speed of sound to a high accuracy (typically +/-0.5%) by analysis of pressure ripple measurements

- in-built diagnostics for tracing measurement faults

- in-built transducer calibration procedure

- customisable fluid property database

- wide range of output options

- high quality, flexible graph plotting

- mathematical modelling of impedance with automatic fitting to measured data

Version 4.10 new features

- real-time signal display during data acquisition

- programmable, precise motor speed control

- ISO 10767-1 compatibility settings

- Mathematical modelling of hose characteristics

Axial piston pump

This figure shows some typical measured flow ripple waveforms for an axial piston pump. The most striking feature is the reverse flow spike which occurs repeatedly when the delivery port starts to open and the fluid in the cylinder is suddenly pressurised. This increases with pressure. We can also see a smaller ripple due to the sinusoidal motion of the pistons.

This pump contained no relief (silencing) grooves in the portplate and so was very noisy. The reverse flow spikes could be reduced by the use of relief grooves. It is flow ripple measurements such as these that could help improve design of relief grooves and let us examine the effect of the reverse flow spikes.

This software also allows us to measure the corresponding amplitude spectra that show harmonics at different pressures.

Reciprocating plunger pump

Here we show the measured flow ripple waveforms for a large reciprocating plunger pump, working with 95:5 water-oil emulsion. This is as is used in mining applications. The red line is for a standard pump and the blue line for a pump with modified valves.

This is a typical flow ripple waveform for this sort of pump with the negative peaks occurring when the valves open and close. The modified valves produce a faster response as seen in the waveforms. They also result in a slightly smaller flow ripple, and an increase in volumetric efficiency and reduction in noise. By measuring the flow ripple, we are able to better determine valve timing.

Power steering pump

Here are some typical flow ripple measurements for a power steering vane pump at low pressure (red) and high pressure (blue). These measurements are useful for aiding low-noise pump designs. They are also used to predict pressure ripple in power steering systems. These predictions have helped to improve designs for low-noise systems.

We are also able to measure the source impedance of this pump. The high-quality measurements are accurate over a broad frequency range. The software is able to identify and reject any 'outliers' in the data. We need to be able to measure the source impedance to determine both the pump's flow ripple and predict pressure ripple in circuits.

Flexible hose

Hoses can have a very strong effect on fluid-borne noise levels. They generally exhibit very complex fluid-borne noise characteristics. This is because of wave behaviour in the hose wall as well as in the fluid. Having accurate flexible hose models is essential for system modelling. Yet, it's difficult, if not impossible, to measure the dynamic parameters for such models by traditional means.

The fluid-borne noise characteristics of a flexible hose can be described by its impedance matrix. This relates the pressure and flow ripples at both ends. We can measure this using the FBN package as shown in the figure here. This shows the amplitude spectrum of one term of the impedance matrix. The blue lines represent measured data using the FBN package. The red lines are modelled characteristics. The model parameters were adjusted to get the best fit with the measurements, and the curve fitting was performed using the FBN package. We can see a good agreement between model and measurements.