He entered the competition because he felt it had two major benefits – showcasing the breadth and significance of the University's research to the public, and also personally for him to exercise the skill of explaining a very complex research area in an engaging way.

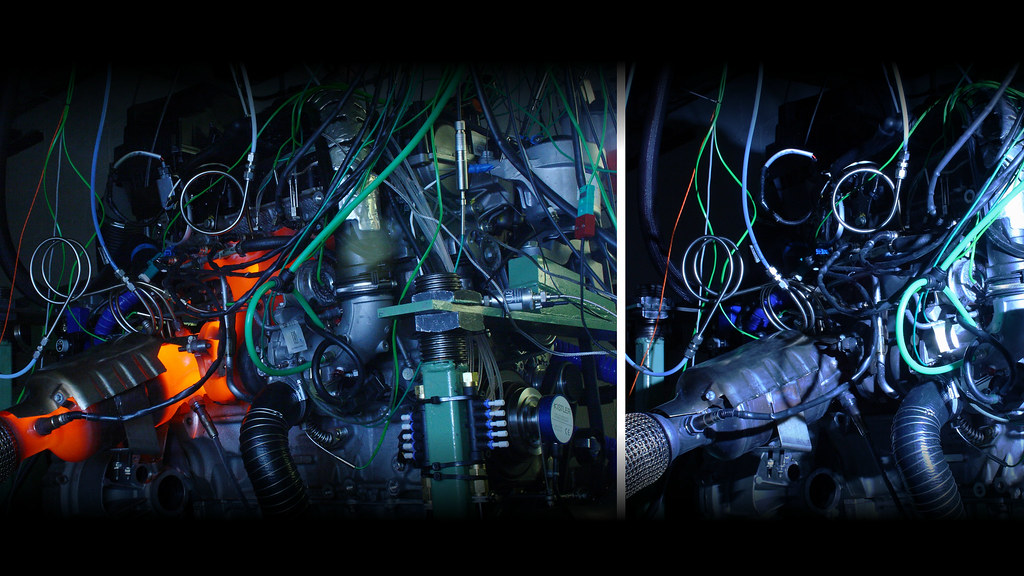

Dr Burke's research takes place in Bath's new £800K Turbo Centre which has been designed to focus exclusively on the development of low carbon turbocharged engines.

He said: "The research we are doing through the Centre will have an impact on everyone – it is key to delivering fuel efficiency and affordable transportation, so will make a difference to anyone using a vehicle. Therefore being able to explain our work to the public is very important."

With the deadline of 2020 for the UK’s carbon targets looming, immediate action is required to address the emissions generated from vehicle use. While many alternatives to fossil fuels are being explored, engineers from the University of Bath say these will not be ready to contribute to 2020 targets.

Key technologies aimed at reducing carbon emissions from transportation are hydrogen fuel cells, electric vehicles and biofuels. Dr Burke believes that none of these alternatives are ready to replace our reliance on fossil fuels for mass market vehicles in the near future, making it necessary to focus on improving the technology already used in mass market, fossil fuel burning vehicles.

To do this, the new centre in Bath aims to develop new downsizing technologies that can be applied to both petrol and diesel engines, allowing them to reduce fuel consumption while still giving the performance of a large engine.

The centre is carrying out its work in collaboration with the UK’s leading vehicle manufacturers, Ford and Jaguar Land Rover, as well as turbocharger manufacturer Cummins Turbo Technologies.

Dr Burke said: "There is a significant gap between the automotive industry and turbocharging manufacturers, so our activities through the centre are working to encourage a more open approach to design with collaboration between all elements of the industry."

By incorporating turbocharging into smaller engines, power can be maintained while significantly decreasing the size of the engine and the amount of fuel required to run it.

Working with leading vehicle manufacturers ensures the knowledge achieved through this research can be taken up in industry at a faster rate. This is supported by Bath’s EPSRC funded Knowledge Transfer Account which looks at developing innovative ways to accelerate the translation of research outputs into business opportunities.