Developing an alternative to palm oil from waste resources, using yeast

We're using energy-efficient microwaves and unique fermentation processes to develop a palm oil substitute from lignocellulosic waste.

Palm oil is widely used in food, cosmetics, personal care and bio-energy industries. However, the production of this plant-derived oil has led to mass deforestation, loss of biodiversity and the destruction of habitats critical for rare and endangered species. We're investigating sustainable ways to produce an alternative that could help reduce the environmental and social impacts of palm oil production.

Our project aims to develop a pilot-scale, multi-product biorefinery. Coupling breakthroughs in low-energy biomass treatment with unique fermentation, we'll produce a microbial oil and other marketable high-value products.

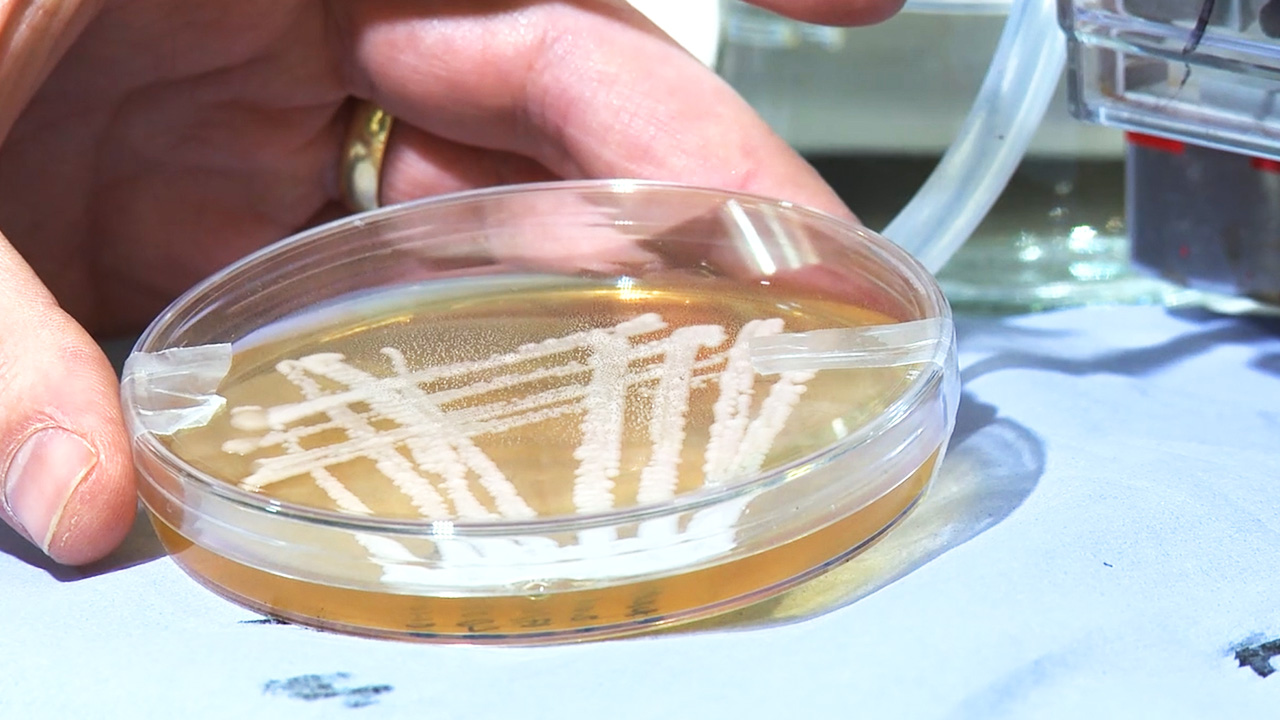

The oil we produce from the yeast Metschnikowia pulcherrima is a suitable palm oil substitute. The feedstock for this process is obtained through an innovative one-step microwave process which depolymerises (breaks down) waste lignocellulosic material (plants biomass) that is used by the yeast. Using waste removes the need for agricultural land to cultivate material, and thus helps to reduce any impact from food crop displacement.

Our research will:

- use microwave technology as a scaled continuous route to depolymerising lignocellulosic feedstocks. This is done without acidic or enzymatic hydrolysis

- demonstrate pilot-scale fermentation and continuous processing of a robust, oleaginous (oil producing) yeast strain. This is carried out under a range of feedstock conditions to produce a microbial oil and other high-value compounds

- enhance Metschnikowia pulcherrima as an industrially functional yeast. This will be achieved through strain screening for desirable traits, adaptive laboratory evolution and genetic improvement

- design an environmentally and economically sustainable, multi-product biorefinery system