The University of Bath and SAIC Motor UK Technical Centre are collaborating on a project to identify the most efficient conditions for the optimum performance of gasoline particulate filters (GPFs), to help minimise vehicle impact on the environment.

The ‘GPF Burn rate and Low Temperature Reactivity’ project will last 14 months and utilise the University’s state of the art Chassis Dynamometer in its Centre for Low Emission Vehicle Research (CLEVeR).

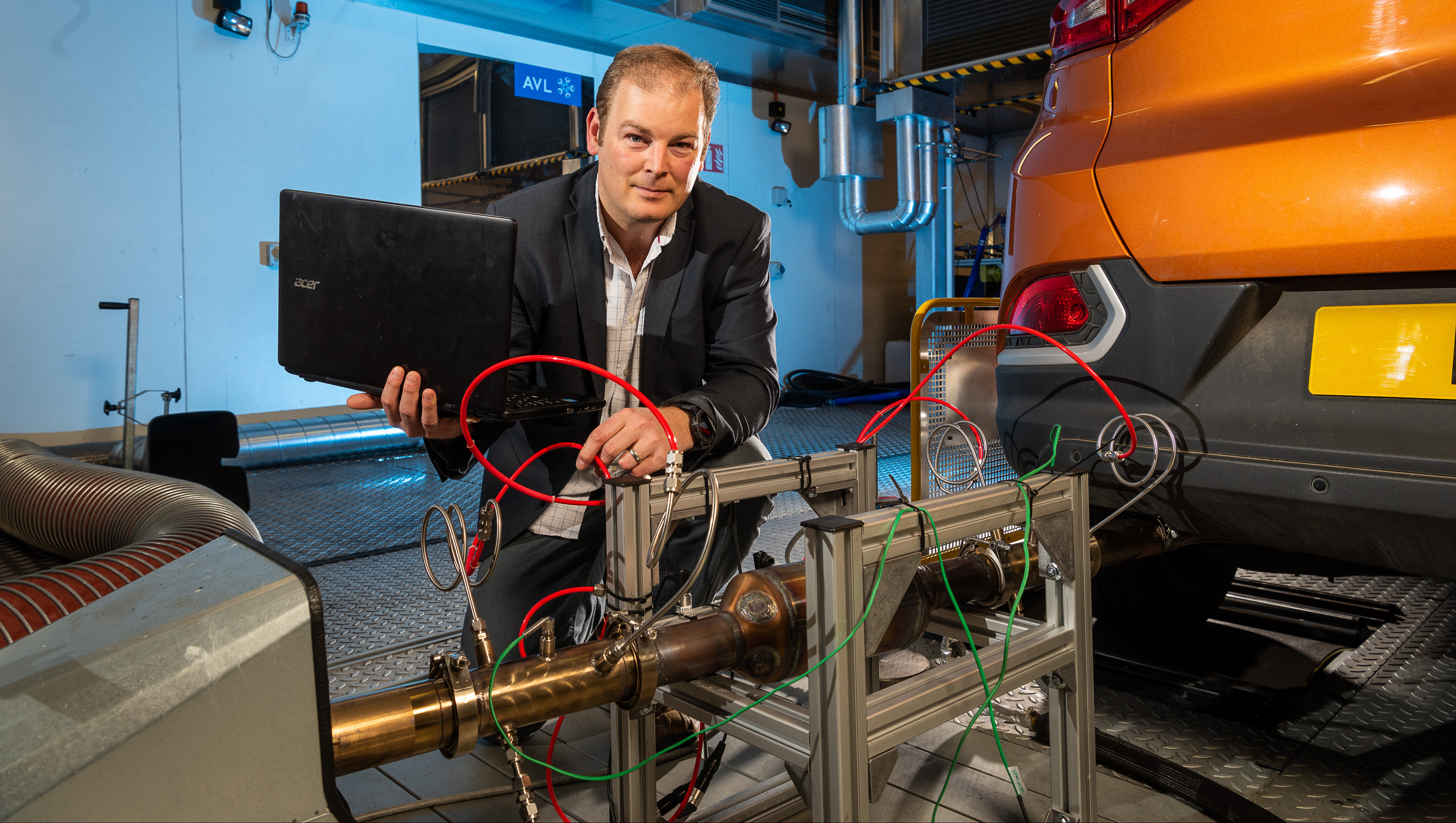

The researchers at Bath are designing a new rig capable of varying the temperature and composition of exhaust gasses entering automotive after-treatment system components – such as GPFs, in order to identify the optimum conditions for the soot burn rate of GPFs.

A test vehicle will be put through its paces on the University’s ‘rolling road’ with the bespoke rig enabling the temperature and exhaust gas composition entering the after-treatment components to be controlled.

GPFs ensure the particulate emissions from a petrol combustion vehicle are kept to a minimum and within the latest Euro 6 standard emissions requirements. This is achieved by the GPF trapping and safely removing harmful particulates from exhaust gasses. Particulate filters can become blocked over time requiring them to complete what is known as a regeneration cycle; where the temperature and gas composition in the engine enables the particulate filter to safely burn off particulate matter trapped in the filter.

Using this new rig, the researchers are also investigating the performance of novel catalyst washcoats and coatings for reducing the temperature at which harmful emissions begin to be converted into the more benign species - water, nitrogen and carbon dioxide. In better understanding the impact of catalysts on the temperature needed for conversion to occur, the researchers hope to be able to minimise the time taken for the catalysts to become operational after the vehicle has been started and reduce vehicle emissions under real world driving conditions.

This work will support SAIC Motor’s gasoline vehicle after-treatment development programme and feed into SAIC Motor’s global product development activities in the UK and China.

SAIC Motor expects this partnership with the University of Bath will contribute to its knowledge of GPFs and catalyst formulations, supporting the company’s rapidly growing sales around the World.

Project lead and Associate Professor in Automotive Engineering in the University of Bath’s Institute for Advanced Automotive Propulsion Systems (IAAPS), Dr Chris Bannister, said:

This research project is an exciting opportunity to widen and build on the existing collaborative relationship with SAIC Motor, and utilise the experience that the University’s Powertrain & Vehicle Research Centre (PVRC) has built up over many years to help reduce the impact of vehicles on the environment.

Reduction of vehicle particulate and gaseous emissions, particularly in urban areas, is a real focus for automotive OEM’s, and it is fantastic that the University of Bath can make a real contribution with this research.

Dr Alexis Manigrasso, After-treatment Research - Lead Engineer, Advanced Engines at SAIC Motor UK Technical Centre, commented:

We're really pleased to be working on this project with the team at Bath. SAIC Motor is committed to minimising the impact of our vehicles on the environment and this work will contribute to that aim. We hope that this project will further strengthen the existing collaborative research relationship between SAIC Motor and the University of Bath and lead to further, multi-disciplinary, projects in the future.

The University of Bath is to lead the way in the development of future generations of ultra-low emission vehicles, through its Institute for Advanced Automotive Propulsion Systems (IAAPS). IAAPS will be a global centre of excellence, delivering transformational research and innovation into advanced propulsion systems.

Based at the Bristol and Bath Science Park, IAAPS is scheduled to open in 2020 and will exploit the engineering expertise of the University of Bath for the benefit of the UK’s automotive industry, generating economic growth and attracting sector-related businesses to the region.