A loss-on-drying test aims to determine the amount of any kind of volatile matter in a sample when it is dried under specific conditions. It is useful for quality control but also in research, e.g. to quantify the moisture or any solvent contained in the material.

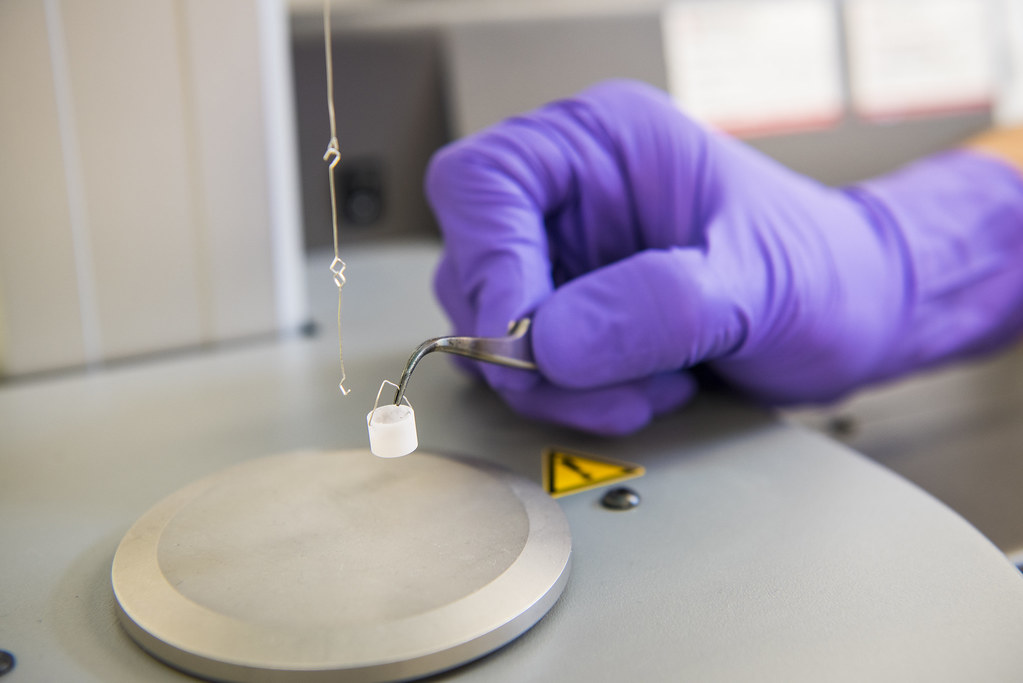

The procedure is straightforward: a specimen is maintained at a constant temperature while its mass is monitored. When the mass no longer decreases or after a specific amount of time, the mass loss of the specimen is recorded: it corresponds to the amount of volatile matter extracted. The experiment is performed in a thermogravimetric analyser (TGA), which monitors mass and temperature in function of time. The TGA has a microbalance capable of measuring mass variations down to 10 μg and a furnace capable of maintaining a temperature within ± 2 °C, as required by the standard method (ASTM E1868-10 standard test method for loss-on-drying by thermogravimetry).

To detect the mass loss most accurately, the mass loss rate is monitored: it is simply the negative derivative of mass with time. A common criterion for the detection of the end of drying is to wait until the mass loss rate is less than 0.1 %/min for 15 min (see ASTM E1868-10). The isothermal temperature is chosen with respect to the thermal stability of the material, which can be evaluated by a preliminary thermogravimetric test. The test must obviously be performed several times to estimate the uncertainty on the final result.

This test method is applicable to a large variety of materials, either solids or liquids, even mixtures, so long as the major component is stable at the temperature of drying.

Read this application note to learn how this technique works in practice with the analysis of poly(methacrylic acid-co-ethyl acrylate) 1:1 as an example.