The industry as a whole is increasingly focused on meeting consumer demand for engines that offer greater fuel efficiency and reduced emissions. But this needs to be achieved without any compromise in power delivery, performance or vehicle noise.

The latest finding from the University of Bath proves it is now possible to reduce engine size and CO2 emissions without impacting an engine’s performance. In tests, the 60 per cent downsized, highly pressure-charged 2.0 litre petrol engine maintained the performance of Jaguar’s current 5.0 litre V8 engine, while reducing its CO2 emissions by more than a third (36 per cent).

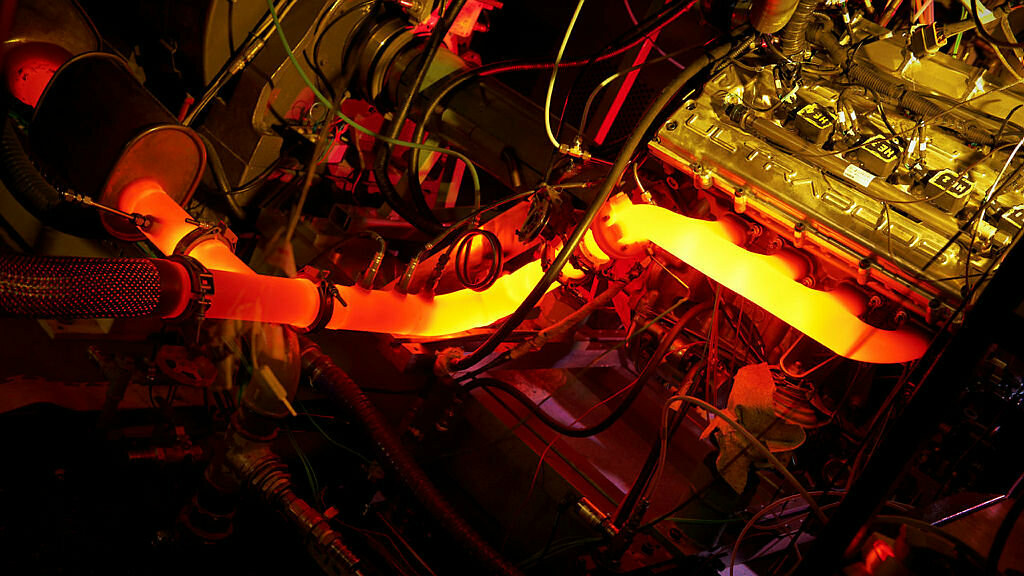

The £4.2m ‘Ultraboost for Economy’ project commenced in September 2010 and was funded jointly by the UK’s innovation agency, the Technology Strategy Board with industry partners Jaguar Land Rover, Lotus Engineering, GE Precision Engineering, CD-adapco and Shell. Part of the Technology Strategy Board’s Low Carbon Vehicles Innovation Platform, the project demonstrates industry wide commitment to reducing vehicle CO2 emissions.

Our Powertrain and Vehicle Research Centre (PVRC) is a world leading automotive research facility, where engines and complete powertrain systems can be analysed and optimised in controlled environments that closely replicate on-road conditions.

Professor Gary Hawley, head of the PVRC said: “This exciting collaboration between industry and academia has used engineering, design and combustion modelling skills to create a new concept engine that combines gasoline levels of engine refinement with diesel-like fuel economy. The University of Bath’s cutting edge research is pushing internal combustion engine technology to new limits in fuel efficiency.”

Ron Lee, Director of Powertrain at lead partner Jaguar Land Rover, said: "Ultraboost is a flagship research project for Jaguar Land Rover. The contribution of the University of Bath’s Powertrain and Vehicle Research Centre has been in the development of the boosting and thermal systems to achieve extreme levels of downsizing from which significant levels of fuel economy improvement follow. We are now looking at the potential for incorporating some of the learnings from this project into future engine designs."

In a further development of this project, the University of Bath will now examine the reasons why the concept engine achieved these targets and explore some of the remaining limits to extreme downsizing, concentrating on the engine combustion system.

In a separate initiative, the Technology Strategy Board’s Smart Scheme is funding a joint research project by the University of Bath and Torotrak to optimise variable drive supercharging (V-Charge) technology and help bring it to market.

The 18-month project will examine how a state-of-the-art downsized petrol engine combined with a variable supercharger performs at a system level. The research will examine the interactions with the V-Charge unit and aims to optimise performance to deliver good low speed torque, fast transient response and excellent fuel consumption.

“V-Charge overcomes the main barrier to engine downsizing by providing near instant response at any engine speed through the use of a supercharger with a mechanical variable speed drive, giving a small engine the performance feel of a larger, naturally aspirated unit,” said Andrew De Freitas, Torotrak’s Programme Manager.

Dr Sam Akehurst commented: “Engine downsizing has become the norm in passenger cars however one of the limitations of further downsizing is the transient performance and low speed torque of these very small engines. This technology addresses both of these issues and should allow us to push downsizing even further than is currently feasible. To be involved in an experimental study of this innovative technology is very exciting.”

For full details of the research published see the paper: 'Ultra Boost for Economy : Extending the Limits of Extreme Engine Downsizing'

If you are interested in this story, you may also like to see: