Team Bath Racing (TBR18) which is made up of undergraduate student engineers from the University of Bath’s Department of Mechanical Engineering, competes annually at the Formula Student competition. This is Europe's most established educational motorsport competition, run by the Institution of Mechanical Engineers (IMechE).

Formula Student (FS) challenges student engineers to design, build and race a single-seat racing car in one year. Nearly 700 teams from across five continents compete at the 15 possible FS competitions across the globe. The competition scrutinises a variety of aspects of each team’s racing car, ranging from manufacturing cost and vehicle design, to on-track performance metrics such as vehicle acceleration and fuel efficiency, and ultimately race pace.

The annual UK event at Silverstone in July is one of the largest events in the FS calendar, welcoming over 95 teams from all over the world. It is also the only FS competition which pits combustion and electric vehicles against each other. The University of Bath is the only UK university to enter a combustion and electric team to this event.

For many years, TBR has been one of the top UK FS, including a record world ranking of 3rd out of 554 teams in 2016. Building upon previous year’s success, TBR18 have stated their ambition to win this year’s FS UK event and at the conclusion of the season be in the top 10 global combustion team out of 556 teams from around the world.

Last year, in the Class 2 event, which consists of three individual tests – car design, cost and sustainability, as well as the quality of a business pitch – TBR18 performed extremely well and were named overall winners. Over the past 12 months, the team has worked hard on further improving their car’s design and performance as they look to compete and win this year’s Class 1 event.

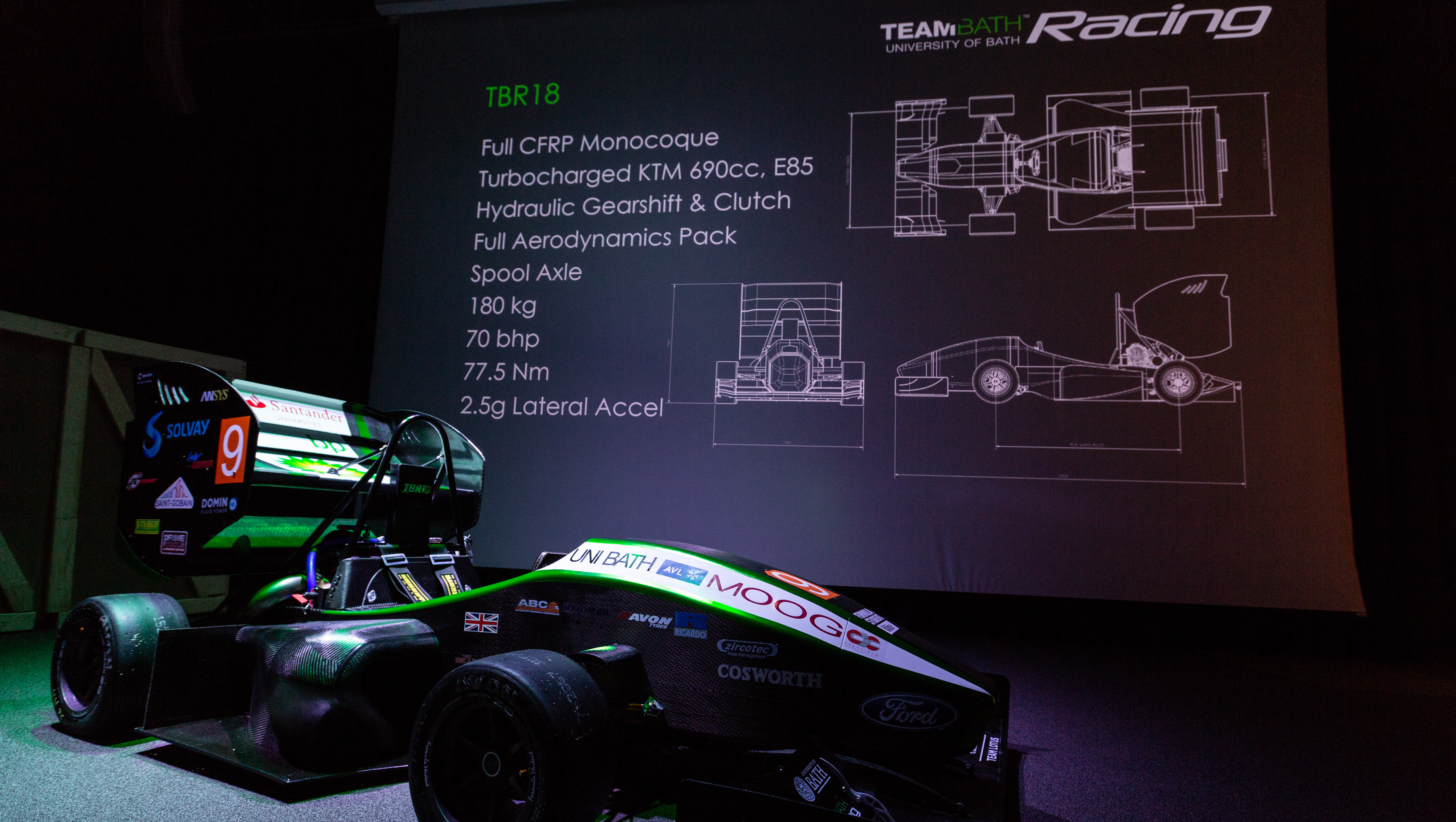

The team of Bath engineers have just unveiled their 2018 car at a jam packed launch event. This car is a brand new design with the most significant change being a new engine, moving away from the 510cc engine that has powered the team since 2015, in favour of a KTM 690cc single cylinder unit. The team has heavily modified this, adding a turbocharger, and switching the fuel from standard petrol to E85, a more powerful and environmentally friendly mix of 85% ethanol and 15% petrol. This has led to the car producing an impressive 70 bhp and 77.5 Nm.

Other significant changes include a brand-new carbon fibre monocoque chassis, magnesium wheels, additive manufactured brake callipers, uprights and hydraulic manifold - which has resulted in an 82 per cent weight saving - and a brand new aerodynamics package. All of these changes have been made to make the car as light as possible – now weighing just 180kg – and as powerful and responsive as possible.

Nick Upjohn, TBR18 Team Manager, said:

It’s such a delight to finally reveal to everyone the car we have been working on since February 2017. So many hours of hard work and dedication from this year’s fantastic team has gone into taking this project from ideas written on a whiteboard to a working race car, for which the team can be immensely proud. We still have plenty of work to do, preparing for our static events as well as the dynamics, but we’ll be ready for our competitions in the UK, Hungary and Austria.

TBR18 open their season at FS UK in July and just three days after will travel to Hungary to compete at Formula Student East. This hugely competitive event will see some of the very best teams from around the world compete against each other. After FS East, the team will travel to their third and final competition, Formula Student Austria at the iconic Red Bull Ring Formula 1 Circuit in the mountainous region of Spielberg.

Dr Kevin Robinson, Senior Lecturer in Department of Mechanical Engineering and TBR academic tutor, added:

This year’s car is an evolution of many if the things we have done well in recent years together with some significant new innovations. This will be the first Formula Student car to feature a bespoke hydraulic system which operates the clutch and gearshift, and includes several parts made using cutting edge additive manufacturing techniques to minimise mass. It is the most advanced car we have ever built and the big challenge will be to overcome the teething troubles before the competitions begin in July.

To keep up to date with the progress of TBR18, visit

Website: www.teambathracing.com Twitter: @TeamBathRacing Facebook: Team Bath Racing Instagram: teambathracing LinkedIn: Team Bath Racing