An increasingly important part of synthetic chemistry and industrial manufacture is process monitoring and control and feedback of product quality and control, ideally in real-time. It is already possible to analyse the output of a chemical reactor in real-time, allowing for direct feedback to adjust parameters within the experimental set-up to optimise a result.

Recently, the Dynamic Reaction Monitoring Facility (DReaM) within the scope of the Material and Chemical Characterisation Facility (MC²) partnered with the group of Prof. Tanja Junkers at Monash University to investigate how Diffusion Ordered NMR spectroscopy (DOSY NMR) could determine the molecular weight of products in a polymerisation reaction in real-time, allowing for the optimisation of the synthesis.

RAFT polymerisation

Reversible Addition Fragmentation Chain Transfer (RAFT) polymerisation is one of a number of reversible deactivation radical polymerisation (RDRP) techniques, also known as controlled/living radical polymerisations, that have been developed in recent years. These synthetic techniques combine the ease and simplicity of radical chemistry with the control over reaction output of living polymerisations, particularly with respect to molecular weight and dispersity.

Analysing the reaction products in real time

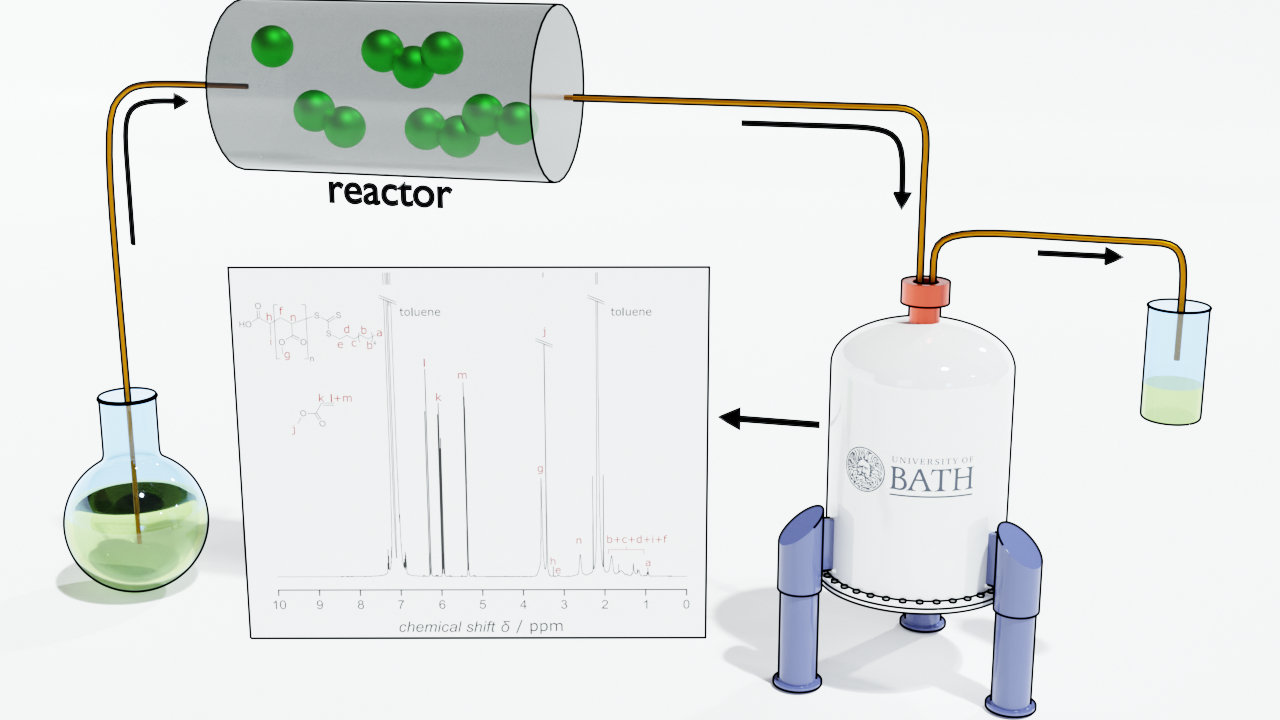

In the experimental set-up used, the RAFT polymerisation of methyl acrylate was performed in flow and the output of the reaction tubing was coupled to a high field flow NMR instrument within DReaM to determine molecular weight in real-time. By adjusting the residence time within the tube, the synthetic molecular weight output of the reaction could be controlled, with shorter residence times leading to lower molecular weight and longer residence times leading to higher molecular weight, and the DOSY NMR data facilitated in situ characterisation of this conversion from monomer to polymer and the associated polymer molecular weight.

Offline versus real-time characterisation

The traditional offline measurement technique of Size Exclusion Chromatography (SEC/GPC) was used to ground truth the data, demonstrating that the NMR analysis technique was accurate to within 5% uncertainty, considerably less than the 20% uncertainty commonly associated with SEC/GPC. Interestingly, the data raised the possibility that DOSY NMR may be used as a universal tool to determine molecular weight of polymer samples, with short analysis times and without the need for extensive calibration. Furthermore the use of this integrated analysis workflow negates the need for manual sampling therefore reducing the possibility of introducing undesirable oxygen into the reaction and analysis system.

This study was published in the RSC journal Polymer Chemistry in open access: J.H. Vrijsen et. al. Polym. Chem. 2020, 11, 3546-3550.