Budget

£5.2 Million

Project status

In progress

Duration

1 Apr 2019 to 31 Mar 2024

£5.2 Million

In progress

1 Apr 2019 to 31 Mar 2024

Industry is the most challenging sector for climate mitigation – it’s energy efficient and there are no substitutes available at scale for the energy-intensive bulk materials - steel, cement, plastic, paper and aluminium. UK FIRES is therefore working towards an industrial renaissance in the UK, with high-value climate-safe UK businesses delivering goods and services compatible with the UK’s legal commitment to zero emissions by 2050, and with much less new material production.

See the UK FIRES project website for the latest updates and publications.

Resource Efficiency is essential for reducing the environmental impact of manufacturing. Progress in achieving it has been slow, but a rapidly changing international context, including Brexit, is giving new emphasis to Industrial Strategy in the UK which creates a unique window of opportunity.

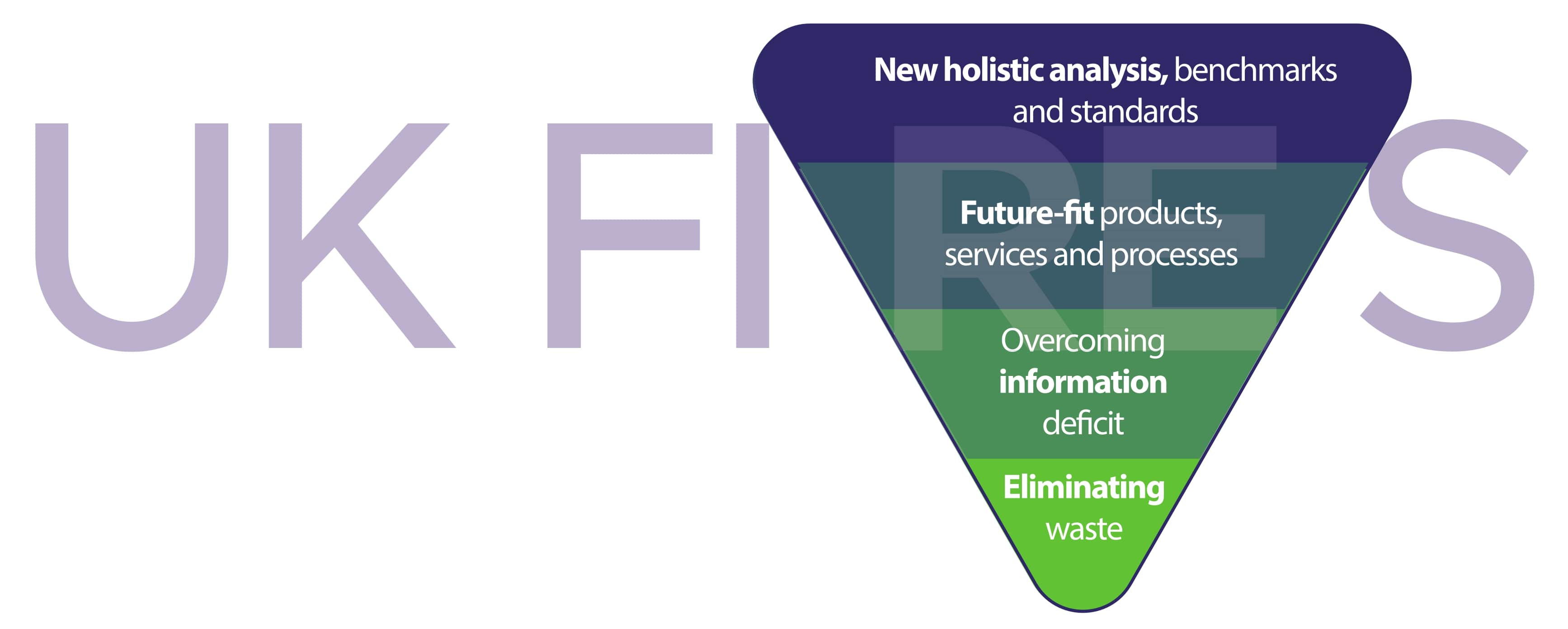

This transformational Programme aims to locate resource efficiency at the heart of a visionary industrial strategy; it will create new world-leading competitive advantage for UK manufacturing by addressing four fundamental barriers to progress:

The Programme brings together nine internationally-leading academic groups and a consortium of subscribing industrial partners. The management strategy, designed for flexibility, aims to integrate existing methods from diverse disciplines to address the application of Resource Efficiency while stimulating exploration of new methodological opportunities where existing approaches are inadequate.

The value of the investment in the Programme will be maximised through an International Advisory Panel to support connections and awareness, a consortium executive committee to determine priorities for strategic analysis, and a supervisory board to ensure financial and legal compliance.

The programme will deliver impact via quarterly strategic analysis reports on resource issues, a programme of policy influence led by an experienced Policy Champion, technological innovations, an annual UK Forum on Resource Efficiency, commercial and open-access software tools, researcher training and multi-channel communications.

The team within the Department of Architecture & Civil Engineering are exploring pathways to full decarbonisation of the UK’s construction industry. This starts with simple but effective carbon-saving changes to modern building designs, followed by minimisation of material usage through radical rethinking of structural design and materials. In tandem, the demand for new construction itself is being questioned – how much new building can we do without?

The project collaborates with 5 Universities and 9 industrial partners

The team is comprised of Professor Tim Ibell, Dr Will Hawkins and Paul Romain from the Department of Architecture & Civil Engineering, as well as Dr Rick Lupton and Dr Sam Cooper from the Department of Mechanical Engineering.

The project is funded by Engineering and Physical Sciences Research Council (EP/S019111/1).

For more information

Visit the UK FIRES WebsiteIf you have any questions about the project.