Designs for a low-cost, 3D-printed blood-oxygen sensor have been shared by University of Bath engineers to help in the fight against Covid-19.

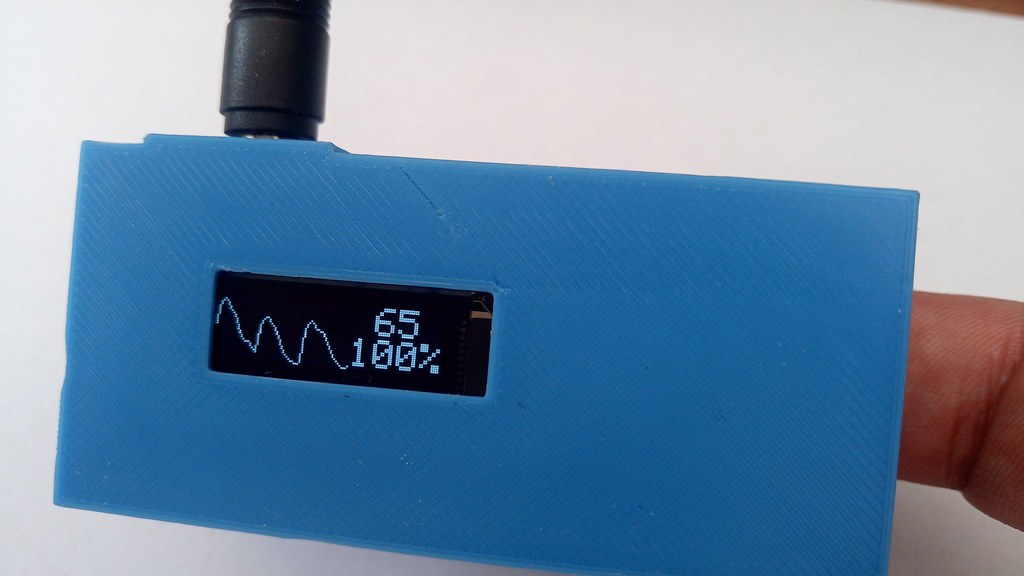

The do-it-yourself ‘Open Oximeter’ sensor, designed by a team of engineers and scientists, can be created by anyone with a 3D printer and basic electronics skills. Costing less than £10 it will accurately monitor a person’s blood-oxygen levels - a key symptom of Covid-19.

Based on existing commercial sensors, the oximeter is worn on a finger clip and measures the reflection of different wavelengths of light, tracking the wearer’s heart rate and saturated percentage of oxygen (SpO2).

The design, which comprises a sensor, readout electronics and software, has been published in the Journal of Open Hardware. The design files have been shared on GitLab.

It was created in response to the first wave of the pandemic in 2020, during which staff from the University’s Faculty of Engineering and Design produced over 200,000 items of PPE for local healthcare workers, while a further 200,000 items were produced to their designs by local companies.

Dr. Pejman Iravani, a Senior Lecturer in Mechanical Engineering, says: “This project started as a response to a potential shortage of pulse oximeters, given the large numbers of patients all requiring oxygen saturation measurements.”

Professor Peter Wilson, from Bath’s Department of Electronic and Electrical Engineering, adds: “Monitoring blood-oxygen saturation has become a key part of patient care during the pandemic with a particular focus on early-warning of serious illness, so demand for pulse oximeters around the world is huge.

“We hope that by sharing this open-source design, healthcare providers will be able to quickly produce more sensors at a reasonable cost.”

The NHS has recently published guidelines on the monitoring of Covid-19 patients’ SpO2 levels, by using pulse oximeters worn at home. Scientists are working to understand why Covid-19 sufferers’ blood-oxygen levels can suddenly drop without them noticing, in an effect known as ‘silent hypoxia’.

Plans to improve calibration and combat racial bias

The team is now working with the University of Cambridge to develop low-cost ‘phantoms’ - artificial fingers - that can be used to calibrate and validate oximeters. These will also help address the issue of racial bias in oximeters - in that they work more effectively for lighter-skinned people.

Lecturer Dr Ben Metcalfe adds: “The importance of accurate measurements cannot be overstated. A recent study in the New England Journal of Medicine identified quite clearly the racial bias present in current oximeters, which worryingly over-estimate the oxygen saturation among patients who identified their race as Black.

“It is well known that calibration of pulse oximeters (especially for low levels of oxygen saturation seen in many Covid-19 patients) is technically challenging. By creating 3D printed materials with known optical properties we can develop phantoms that will enable calibration at these lower oxygen levels.”

The team received funding from the University of Bath Alumni Fund to create their prototypes.