Ultra Low Temperature freezers (ULTs) are commonly used for storing biological samples for research purposes. However, these specialized freezers consume a significant amount of energy. A single freezer running at -80°C uses as much energy in a year as an average household. Increasing the temperature to -70°C reduces energy usage by 25 to 30%, a considerable amount.

Before the 1980s to 90s, ULTs were set at -65°C or -70°C. However, manufacturers started advertising temperatures around 10°C colder, and this change requires significantly more energy. Even though lower temperatures are advertised to improve sample stability or recovery, little evidence suggests it is true. 1

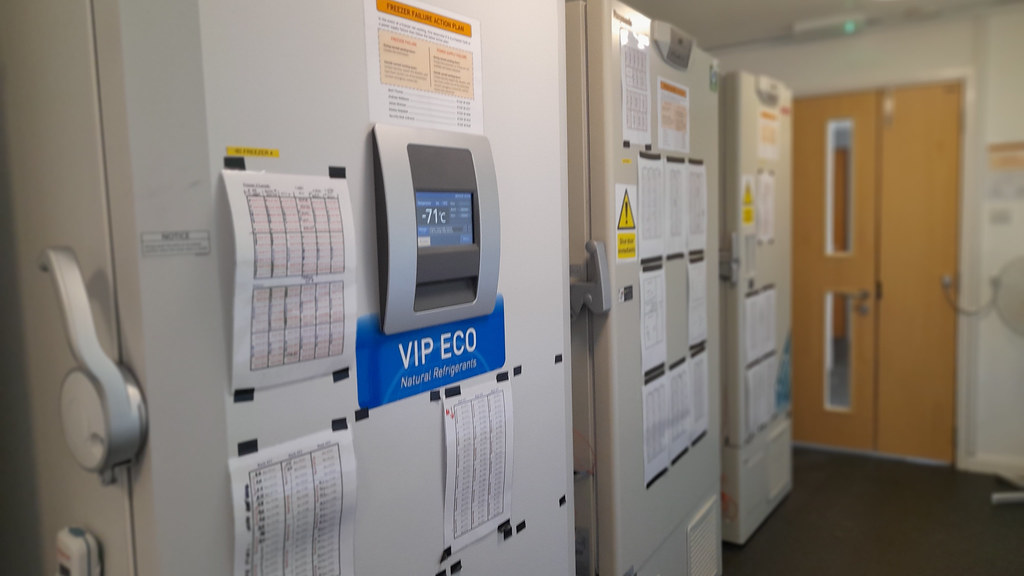

The journey to -70°C

Since the University of Bath declared a climate emergency in 2020, laboratory users have taken the initiative to explore new sustainable measures to improve efficiency and lab sustainability through the Laboratory Efficiency Assessment Framework (LEAF). In 2023, one of the most effective solutions that has been successfully implemented has been to raise the temperatures of the ULT freezers.

Professor Ed Feil in the Department of Life Sciences supports this eco-friendly approach and says, "Turning the ULTs up is a great example of a very quick win in terms of energy usage and sustainability. Surprisingly, this modest change in temperature has a big effect on energy usage, and significantly reduces strain on the freezer themselves, prolonging their life span. Importantly, there are no significant problems regarding the viability of important samples by making this change, and the speed with which the freezers warm to an unacceptably high temperature in the event of a power outage is only marginally shorter. In sum, this is a great example of an incredibly simple change that all labs could make immediately, with significant energy savings with no appreciable downside.”

Laboratory Technician Mark Thomas states, “With the University declaring a climate emergency and the laboratories seeking to gain LEAF accreditation, we, the technicians in the Department for Health, decided one way to tackle both issues would be to raise the temperature of our ULTs to -70°C. Given that the department has six freezers, this significantly saves energy and money. We presented evidence to the research staff that increasing the temperature would have no impact on the stability of the samples stored in the freezers. With no objections from the staff, we increased the temperature of the freezers, and subsequently have had no issues”.

The outcomes of raising the temperature

- This year, 24 ULT freezers at the University have had their temperatures raised. Eight labs in the Department for Health and 16 labs in the Department of Life Sciences have implemented this sustainable measure.

- This approach saves energy costs, reduces the carbon footprint, and extends the lifespan of the equipment.

- Raising the temperature from -80°C to -70°C can lead to a 25 to 30% reduction in energy consumption, which translates to around £500 in savings per freezer on an annual basis.

This environmental solution has been helpful in the university's journey towards a more sustainable future, and it has also supported wider change. Warming these freezers is important progress for the Department for Health and Department of Life Sciences, and has contributed to the former achieving 100% Bronze LEAF certification in 2023.