"There are so many reasons why I chose to study my degree at Bath including the University's connections to industry and its incredible reputation for placements. I wanted a first-hand experience of both the academic and professional life and I knew this degree could give me exactly that."

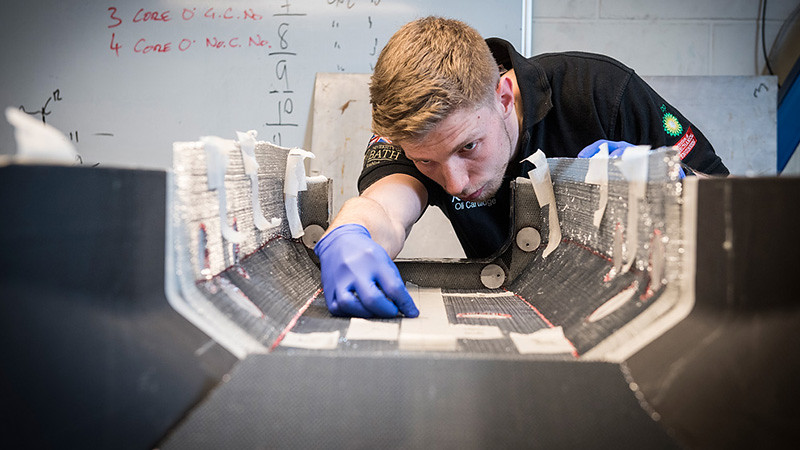

Rafa has just completed his undergraduate degree in Mechanical Engineering with Manufacturing and Management. As part of the course’s final year, students carry out an individual project in an area of their choice. Rafa’s project analysed alternative cooling techniques to improve machine operations for difficult materials.

Taking Bath's manufacturing research further

“I wanted to explore alternative ways to improve the machinability of the nickel-based super alloy, Inconel 718. My supervisor was already researching in this area so my project continued on from his work."

Inconel 718 is used across the automotive and aerospace industries. The material is resistant to high pressure and temperatures, making it perfect for use in gas turbines, turbochargers and more. But machining Inconel is difficult and requires cooling and lubricating techniques. The conventional methods most commonly used aren't as effective as they could be.

Cryogenic cooling techniques are emerging as promising alternatives to conventional techniques. They have unique advantages that make them stand out amongst other green power production technologies and coolant mechanisms.

As part of his project, Rafa created a theoretical thermal model of the cooling system and analysed it using an engineering simulation system. He developed a feasible machining environment that maximised the efficiency of the cooling method.

"My aim was to explore the theoretical feasibility of using a cryogenic cooling device. I wanted to see how successful the module could perform as an alternative to conventional coolants and lubricants. My results proved that the cryogenic module would make a good alternative coolant mechanism."

A rewarding learning curve

"Working on an individual project has been a great learning experience. It’s given me the time to focus in and expand my knowledge of nickel-based alloys, coolants and cryogenic generators. It’s also made me realise how much work goes into a research experiment. Working in a professional research environment has helped my self-confidence grow and taught me perseverance! I've learnt how to deal with unsuccessful outcomes and keep on trying until I achieve the desired results.

"Most of all, I’ve enjoyed the freedom to work on the project at my own pace, set my own deadlines and manage my efforts. This was the first time that my schedule and work ethics were completely up to me. It was scary at first but incredibly rewarding when I started seeing results.

"Finishing this project made me realise the huge improvements I’ve made. This degree lets you learn and develop day on day. I don't think you can really appreciate how much you’ve improved until you compare the first project with the last!"

Opening up future prospects

"I've enjoyed the diversity of units and projects on my degree. When I started, I wanted to specialise in automotive but the range of subjects I studied over the first two years opened up new areas of interest for me. It was this experience that influenced my shift to manufacturing and management. I'm incredibly grateful that my degree allowed me to keep my options open. It's given me the necessary tools and resources to find and pursue my chosen academic career."

"My degree has fired my interest in manufacturing engineering and management. I plan to explore these areas further with a master's in Industrial Systems, Manufacturing and Management.

"I'm very excited to see what the future will bring me. Regardless of what it is, I know that Bath has succeeded in preparing me for future challenges and experiences."