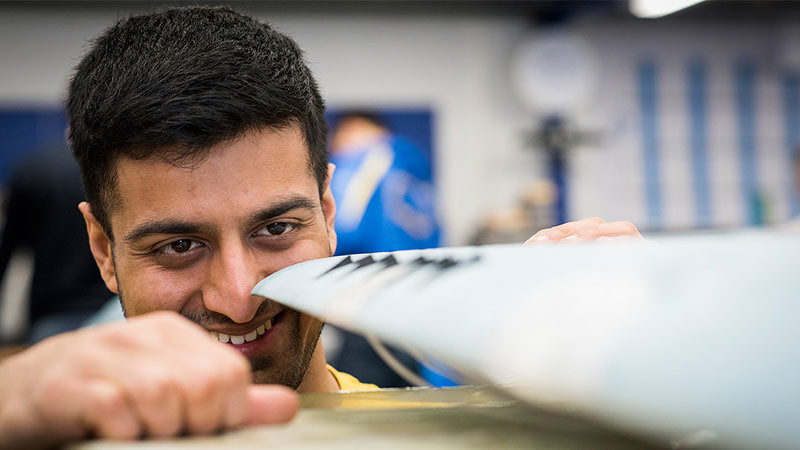

Team Bath Racing (TBR) design, test and build a single-seat racing car to compete in IMechE's Formula Student competition every year. The team takes the car to events across the UK and Europe where it undergoes a rigorous testing process for acceleration, braking and handling.

Developing a new design from scratch

Oli began work on a new car as part of his group business and design project. The project challenges students specialising in mechanical and automotive engineering to design from the drawing board through to end product.

"We begin with a blank piece of paper in the second semester of our third year and work through concepts, feasibility and detailed design in 12 weeks.

"We then go to competition and get judged on our design and essentially change everything. We start manufacture during lectures and exams and finish during our research projects, which focus on a specific part of the car. It’s worth noting that in our final year everything is extra-curricular, so it really is a labour of love."

The project introduces students to aspects of business law, risk assessment and sustainability. It gives students the opportunity to apply their financial, marketing and management skills to a tangible scenario. The car has to be reliable, easy to maintain and low cost. As well as this, the team are also judged by a panel of industry experts on the viability of their business model.

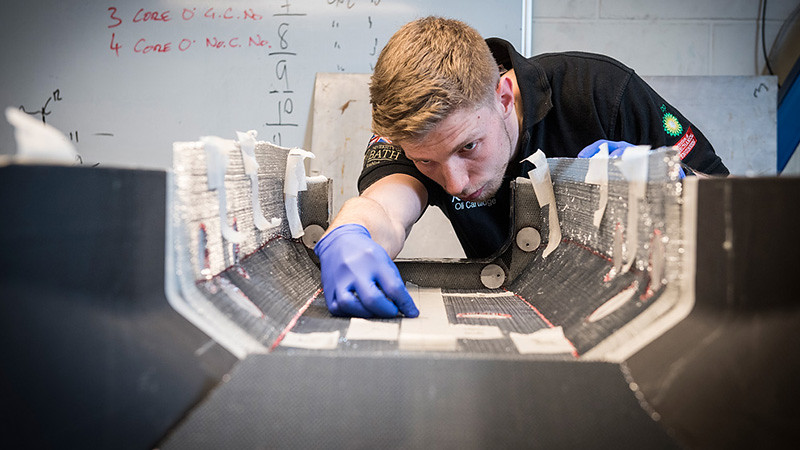

"I think the main thing about TBR is that you have to do every part of it yourself. You learn design techniques, analysis software and its limitations, and manufacturing skills (the hours I’ve spent laying up carbon fibre is definitely into the hundreds). But you also learn the soft skills associated with working in a team and managing people: time management, conflict resolution and adapting to stressful situations."

Going the distance

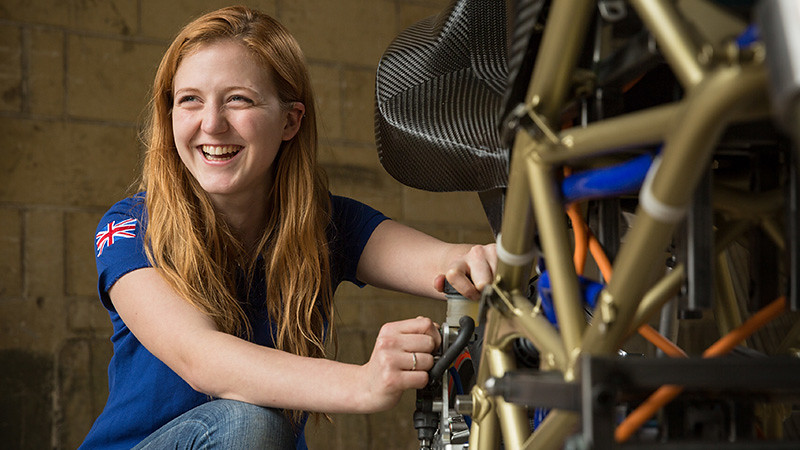

Oli joined TBR in his first year of university after seeing a car during an Open Day. Now he's in his final year and coordinating a team of six engineers as TBR's Chassis Manager.

"TBR was pretty much the reason I came to Bath to study mechanical engineering. Not many things are cooler than race cars, and building your own is a dream job. Fast forward five years and I get to do it every day as part of my degree!"

"My team develops the vehicle's main structure, driver environment, material testing and also the aerodynamic assemblies on the car. Day to day, I am responsible for the design, analysis and manufacture of the chassis itself. This is undergoing a large development this year so there are lots of late nights. But the more you put in, the more you get out. Pretty much every success I’ve had has been as a result of working in TBR. It's great exposure to real-life engineering so it helps with your career as well as your degree. Oh, and because race car!"