Bamboo is commonly considered a low grade building material, used for scaffolding and temporary structures, even though it has a considerable strength to weight ratio – comparable to mild steel.

But variations between bamboo species – and in the strength and density across and along individual stems – hinder its use as building material in applications where stiffness is required.

Guadua - a bamboo species native to South and Central America - has been used for structural applications in small and large scale buildings, bridges and temporary structures, with proven earthquake resistance.

Thanks to its remarkable mechanical properties, the use of round stems of Guadua has been standardised in countries such as Colombia and Peru, which are vulnerable to earthquakes.

Yet Guadua remains a material for vernacular construction, associated with high levels of manual labour and structural unpredictability.

Benefits of Bamboo-Guadua

Bamboo-Guadua is a fast growth woody species of bamboo, native to tropical American regions, that has a number of benefits as a construction material:

- it grows extremely quickly, reaching maturity three times faster than hard woods

- it has a strength comparable to steel

- its mechanical properties - size, lightness and strength - give it superior stability

- it is widely used as a construction material in countries such as Mexico, Costa Rica and Colombia

Developing Guadua for mass production

Héctor Archila, a postgraduate in the Department of Architecture & Civil Engineering, has developed a method to mass-produce standardised flat industrial structural products from Guadua, and to measure and predict their mechanical behaviour.

By subjecting Guadua to thermo-hydro-mechanical treatments that modified its microstructure and mechanical properties he has been able to obtain flat sheets with a uniform density.

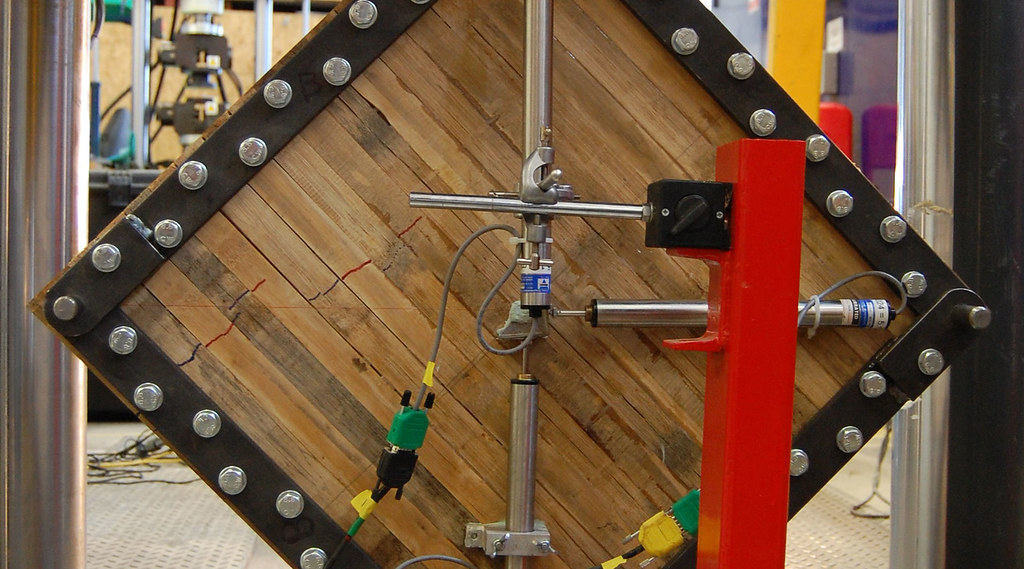

Cross-laminated Guadua panels were manufactured at the University of Bath using the modified flat Guadua sheets, and their mechanical properties evaluated by testing small and large specimens.

The panels were submitted to a test programme in order to characterise their mechanical properties. Digital Image Correlation techniques were used to track the physical deformation and strain in the panels under load. And a finite element model was developed for property prediction, in parallel with the physical test programme.

Using the technique in industry

The project has successfully transformed round stems of Guadua into flat sheets that are used to fabricate engineered Guadua panels – using a technique that can easily be applied industrially.

Applications include load-bearing elements in domestic and industrial buildings, where the flat panels can replace energy-intensive materials such as steel and concrete.