Use our X-ray diffraction service

Discover the X-ray equipment available in the Physical Structure Characterisation Facility.

We have a range of equipment and technical experts to help you gain valuable insight into the arrangement of atoms in crystalline materials.

Discover the X-ray equipment available in the Physical Structure Characterisation Facility.

Discover how we used Powder X-Ray Diffraction to identify a solid deposit formed in pipelines at a water recycling centre.

Learn about the indexation of powder X-ray diffraction patterns and how wide-angle X-ray scattering (WAXS) is used to study protein fibrils.

We offer services and techniques for thermal analysis in which the relationship between a sample property and temperature is studied.

Find out about the thermal analysis and polymer characterisation services at the Physical Structure Characterisation Facility.

Learn how mechanical analysis can be used on polymer powder to detect the glass transition.

Learn how thermogravimetry can be used to determine the amount of volatile matter in a sample.

Learn the methods used to characterise polymers and in thermal analysis in general.

Our Autosorb-iQ-C by Quantachrome Anton Paar determines the surface area, the pore size distribution and the surface activity of solids, in both physisorption and chemisorption modes.

Network will find and investigate materials for applications in renewable energy, drug delivery, water purification and more

We have a range of equipment that can be used to measure the sorption properties of an instrument. Find out how they can be used for your experiment.

Learn about the methods used to determine the BET surface area and the pore size distribution of solids.

We have three different particle analysis instruments each with their own measurable particle size range capabilities. These are the Nanosight, Zetasizer and Mastersizer. They use Dynamic Light Scattering (DLS) and Nanoparticle Tracking Analysis (NTA) to determine particle size distribution and concentration accurately. We offer wet analysis of samples dispersed in solution.

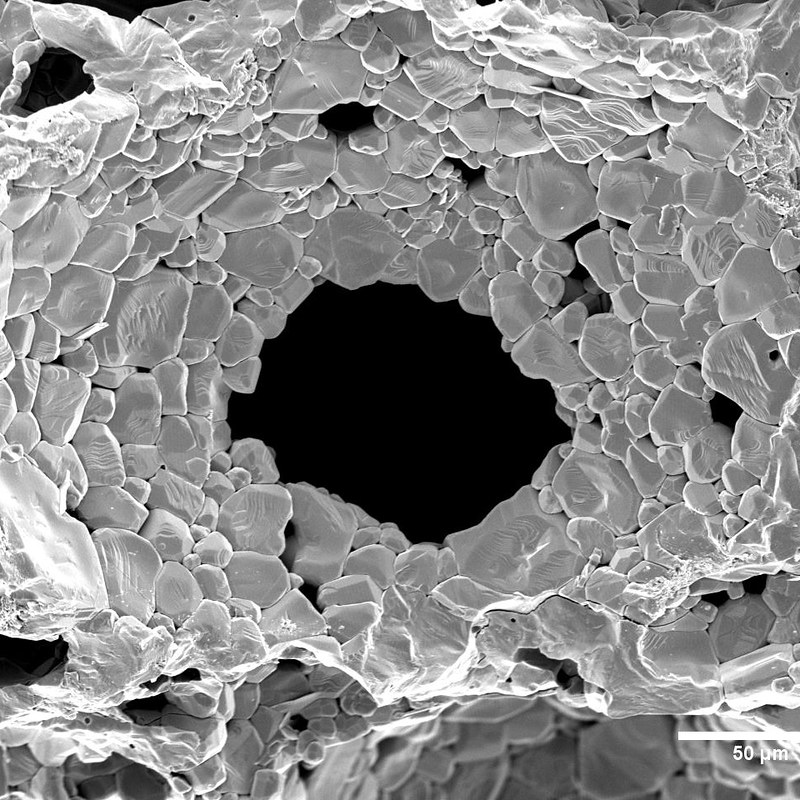

To accurately determine the use of a material, it is important to know its porosity: that is, the pore size, pore volume, pore size distribution and density.

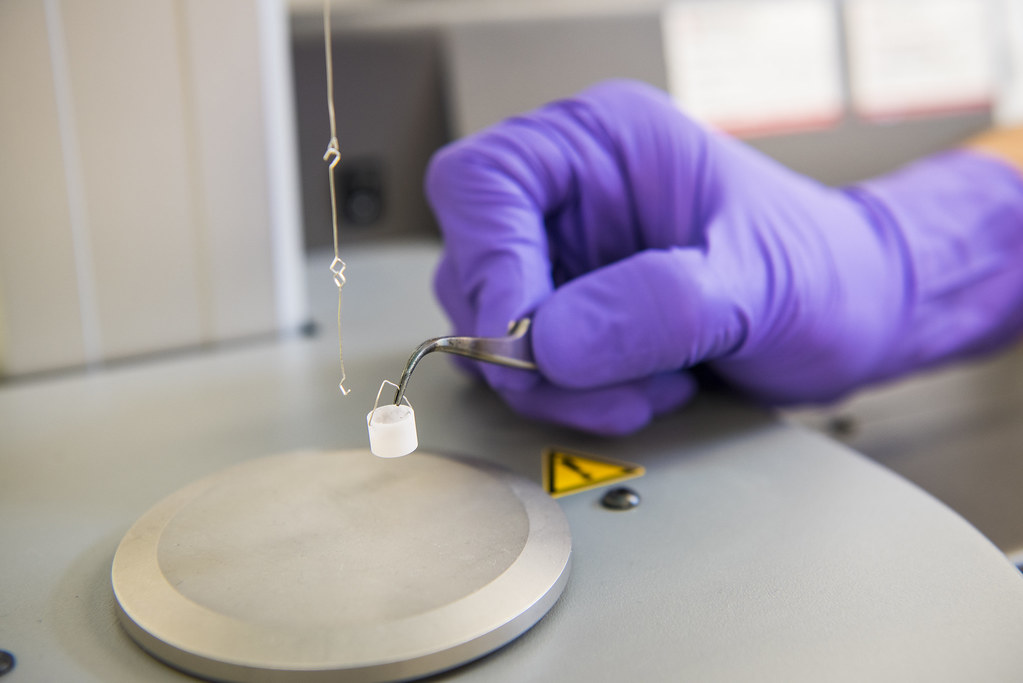

Mercury will not spontaneously penetrate pores by capillary action but has to be forced into the pores by externally applied pressure. The Mercury Intrusion Porosimeter uses this non-wetting property of mercury on most substances. Because the size of a substance's pores directly relates to the pressure the Mercury Intrusion Porosimeter needs to apply to achieve penetration, the instrument can calculate the pore size distribution and volume of a material from the pressure versus intrusion data generated. This data is generated using the Micromeritics (Autopore V) instrument. Tests are performed with a sample of up to 2g, depending on the material's pore volume. Samples can be in the form of a powder or, ideally, as one big piece.

We offer users the ability to determine a broad range of the physical properties of materials using a range of cutting-edge technologies. Among other services, we can determine sorption and thermal properties, and characterise the atomic and molecular structures of new materials.

The Physical Structure Characterisation Facility is part of the Research Infrastructure and Facilities service.

If you have any questions about the Physical Structure Characterisation Facility please get in touch.